8 Types of Gold Ore

Gold mainly appears in the form of natural gold and minerals in the ore such as pyrite, tellurium ore, sphalerite, and gold in gangue, etc. About 70% to 75% of the gold in the deposit is in the form of natural gold, while the other 20% occurs in the form of telluride.

The remaining 5% to 10% is in the form of "invisible" gold, which has been replaced by the crystal structure of various minerals or in the form of tiny particles.

1. Quartz gold ore

Quartz gold ore properties

Gold exists in quartzite. Usually, quartz appears as small stones in large cracks in riverbeds or mountain slopes and has crystals in different colors such as white, yellow, pink, purple, gray, or black. The most common types of quartz with gold ore are rose quartz gold ore and rainbow gold ore.

A high gold-quartz ore contains 25% gold by mass, and it occurs in areas where the bedrock is fractured by tectonic and volcanic activity.

Extraction method of quartz gold ore

Once you find gold in quartz ore, you can extract gold by the flowing steps:

- 1Use a sledgehammer to break the rock into smaller pieces.

- 2Place a steel anvil in a large pan to prevent the loss of the gold contained in the quartz stone.

- 3Look for large pieces of gold that can be collected manually or with tweezers.

- 4Sieve and crush the smallest pieces of gold-containing quartzite in water to collect and extract gold.

- 5Adopt standard placer gold washing methods and then separate small gold nuggets and powder from the ground rock.

2. Silver-gold ore

Silver gold ore properties

Gold and silver ore are rich in silver sulfide and free gold. High-grade silver ore usually has a much lower base metal content. Volcanic activity accompanied by plate subduction will form superheated gold and silver deposits. For example, most superheated gold and silver deposits in Japan form through the precipitation of gold from fountains.

Extraction method of silver gold ore

- 1Use an ammonium thiosulfate solution which is recycled at a temperature of 15-25°C to process silver-gold ore.

- 2The filtrate produced after dissolution is electrolytically extracted with a high alloy electrode at a current density of 200...250 A/m 2 until the electrolyte reaches a concentration of 5-15 ppm Au, 1-100 ppm Ag and 0.1-1.0 g/1 Cu.

- 3Filter out the separated clay and dissolved it in ammonia water.

- 4Dry the clay at 105°C and melt it at 1200°C to obtain Au-Ag alloy.

- 5Get the purity Au and Ag by electrochemical and thermal refining operations.

3. Iron oxide copper gold ore

Properties of iron oxide copper gold ore

The amount of iron oxide copper gold ore is about 10 million to 4 billion tons. IOCG ore contains copper with a grade of 0.2% to 5% and gold with a content of 0.1 to 1.41 grams per ton.

Iron oxide copper gold ore tends to be conical on the edge of granite, or appears as long banded breccia or massive iron oxide ore in faults or shears.

Extraction method of iron oxide copper gold ore

- Crush, grind and classify the copper-containing gold oxide ore.

- Give the ore an alkaline treatment.

- Add certain proportion of chelating agent and sodium cyanide to inhibit the leaching of copper and the selective leaching of gold.

- Use conventional activated carbon in the leachate to adsorb gold.

4. Gold sulfide ore

Properties of gold sulfide ore

Gold sulfide ore is the inorganic compound with the formula Au2S. It is the principal sulfide of gold and decomposes to gold metal and elemental sulfur, illustrating the "nobility" of gold. In nature, the covalent radii of gold sulfide and silver are similar, and the two will form a solid solution.

Extraction method of gold sulfide ore

- Calcinate the gold sulfide ore to remove the antimony.

- Put the slag into the beneficiation process.

- Get the last antimony and gold through another round of calcination of ore slag.

5. Blue clay gold ore

Properties of blue clay gold ore

Blue clay gold ore generally contains a small amount of quartz, a large amount of gold, and a lot of black sand, and this type of gold ore is easy to identify. So If you find blue clay contains a lot of black sand, this may be a very good sign that gold is also nearby. Alluvial gold is most found in blue clay and is in clay-laden gravel or between thin layers of rock.

Extraction method of blue clay gold ore

- Mix evenly the blue clay, mud or silt containing gold with enough water.

- Make this diluted clay flow through a sieve with a diameter of about 120 microns to separate larger particles to avoid affecting the work behind it.

- The separation of large gold particles can be carried out by cyclone method, shaking table, or vibrating screen according to different situations.

6. Tellurium gold ore

Properties of tellurium gold ore

Gold-bearing minerals containing tellurium are called "tellurides". Tellurium–gold deposits differ from normal gold mineralization in their significant content of tellurium‐bearing minerals with a close relation between Au and Te. Tellurides contain native tellurium, altaite, coloradoite, petzite, and calaverite.

Extraction method of tellurium gold ore

Telluride ore is not suitable for direct cyanidation and is usually roasted before cyanide treatment to decompose gold telluride compounds. After calcination, gold is recovered from the telluride ore with the aid of a copper cyanide solution.

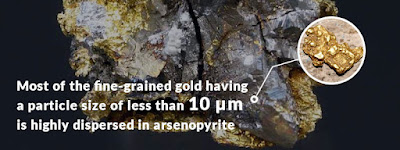

7. Gold in arsenopyrite

Properties of gold in arsenopyrite

Arsenopyrite is also the main gold-bearing mineral, which is closely related to gold. The distribution of gold in arsenopyrite is similar to that in pyrite. Most of the fine-grained gold having a particle size of less than 10 μm is highly dispersed in arsenopyrite.

When the arsenopyrite ore is crushed and ground, it occurs that the pores of the ore have been cracked and the gold has been dissociated.

In the arsenopyrite gold mine, the Au content is 72.27%, the Ag content is 27.73%, the As content is 38.79%, the S content is 24.29%, and the Fe content is 36.92%.

Extraction method of gold in arsenopyrite

- 1A common practice in processing pyrite gold ore is to remove as much gold and sulfide as possible by gravity treatment and/or flotation.

- 2Generally, arsenopyrite concentrate is contacted with mercury to recover the free gold content.

- 3The mercury and amalgam are recovered by washing on the amalgam plate, and then the resulting product is evaporated to recover the mercury and produce gold sponge residue.

- 4The gold sponge is fire-refined to produce gold ingots.

- 5Tailings often contain large amounts of residual gold and need to be transported to a smelter for further processing.

8. Granite ore gold

Granite gold ore properties

Granite and plutonic rocks belong to crystalline rock and ore veins, which are also the main source of gold. The muscovite granite also contains gold, which have formed relatively black iron due to the intrusion of gold deposits into the rock mass.

Gold is also scattered on the top area of granite containing magnetite and ilmenite. For example, Timbala, the entire gold resources are distributed in a wide range of muscovite granite mines and are composed of medium-grained to coarse-grained rocks .

The scattered gold ores are present in all five deposits, accounting for more than 95% of the total resources of Timbala. Granite gold ores mainly appear in the form of light immersion, in the shape of plates and columns, and are limited to fine-grained mica under the carapace and inner mica layer.

Extraction method of granite gold ore

- 1Wash, filter and grind the granite ore with into smaller pieces.

- 2Put the ground ore into a tank containing a dilute cyanide solution and add zinc. The chemical reaction between a dilute cyanide solution and zinc will separate the gold from the ore.

- 3Use a filter press to remove the gold from the solution.

- 4Use the pulp-in-carbon method by which you should combine carbon with gold to get carbon gold particles.

- 5Put the carbon gold particles into the caustic carbon solution to separate the gold.

No comments:

Post a Comment